The M60 is one of the world's most successful main battle tanks with 15,000 having been produced and serving in the armies of 22 countries.

Read MoreTechnical Data

ISO Group is a Fully Qualified Supply Chain for the Main Assemblies of the M60 Tank

Read MoreMain Assemblies

ISO Group Supports All Maintenance and Overhaul Activity by Providing Quality Spare Parts from our Global Supply Chain

Read MoreOverhaul Solutions

ISO Group offers Modernization Packages for the M60 Series Battle Tank.

Read MoreUpgrade Solutions

ISO Group is a fully qualified supply chain that delivers authentic, genuine, and factory new maintenance spare parts through either Foreign Military Sales (FMS) OR Direct Commercial Sales.

The M60 tank is comprised of over 7000 part numbers, all of which are available through ISO Group. Currently we provide spare parts support for 80% of the world’s M60 Tanks fleets in 12 different countries directly, as well as through in-country resellers and Prime contractors.

Overview

The M60 Series was an all-purpose main battle tank (MBT) designed to have the firepower and armor of a heavy tank and the mobility of a medium tank. ISO Group provides spare parts and solutions for the three main versions of the M60; the M60A1, M60A2, and M60A3. ISO Group has experience in the M60 AVDS 1790 Engine, Drivetrain, Transmission, Track Shoe, Electrical Assemblies, Weapons Systems, and Accessories. Follow the links below for more detailed information.

ISO Group is a leader in the supply of OEM and Aftermarket spare parts and Rebuild Services. Our sales and support team has access and knowledge to more than 120 million unique parts for customers around the World.

M60

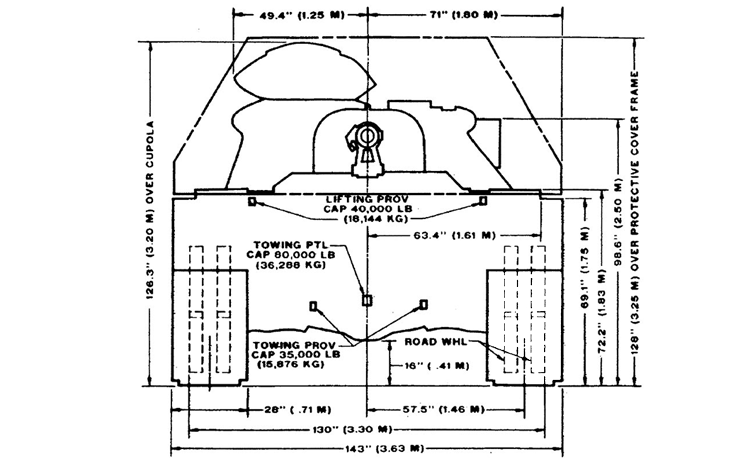

The M60 was an evolution of the M48A2 Patton tank, and bears a strong family resemblance. The new tank was borne out of desire for greater range and increased firepower. Unlike the earlier tank, the M60 has a wedge-shaped front hull and forged aluminum wheels versus the M48A2's boat-shaped front hull and steel road wheels. The new aluminum road wheels on the M60 were interchangeable with the older steel wheels, but were 65lbs (29kg) lighter apiece than the steel wheels. The 105mm gun M68 was a license-produced version of Britain's L7 gun, but was fitted with an eccentric bore evacuator instead of a concentric model in order to provide more clearance over the rear deck. The exhaust for the personnel heater emerged from the front hull roof and ran to the vehicle's right. The first 300 M60s produced were armed with a .50cal M2HB machine gun in a pedestal mount welded to the left side of the commander's cupola due to production problems with the new M85 machine gun. Of these tanks, the first 45 manufactured were made without the cupola itself, also due to production problems. The M60 originally had no shock absorbers, however these were added beginning in 1962, and retrofitted to earlier tanks. Fifteen of the earliest M60s produced had insufficiently thick hull armor, and were therefore used by the Armor School as training tanks. M60 turrets had three lifting eyes. On early turrets these were arranged with one behind the 105mm gun and one on each rear corner. On later turrets this was reversed, with one on each front corner and a single eye on the rear of the turret.

M60A1

M60 was quickly followed by M60A1, and the major redesign was the turret. M60A1 featured a longer, "needle-nosed" turret, which placed the 105mm gun 5" (13cm) forward of where it would be in M60's turret. M60A1 also featured increased armor protection, improved location of the brake and accelerator pedals, hydraulic instead of mechanical linkages for those pedals, and improved seats. Friction snubbers were installed on the first two and last road wheels from the start of production.

There were many improvements to the M60A1 over its lifetime. Top-loading air cleaners, which were easier to maintain and provided better air filtration than earlier versions, were introduced in 1971. A stabilization system for the M68 was introduced in 1972; M60A1s fitted with stabilization were designated M60A1(AOS) for Add-On Stabilization. M60A1(RISE), or Reliability Improvements for Selected Equipment, was fielded in 1975. M60A1(RISE) had a more reliable engine with the top-loading air cleaners; stronger cylinders; improved starter, fuel injection lines, and nozzles; and better turbo-superchargers. The T142 track allowed for longer track life since the rubber pads were replaceable. The top loading air cleaners were armored starting in January 1977. Improvements were also made to the tank's electrical system. M60A1(RISE)(PASSIVE), first seen in 1977, was fitted with a smaller gun shield-mounted searchlight that produced white and infrared light, and the gunner and commander were given passive night vision sights. The M68 gun tube was also wrapped in a thermal shield to prevent barrel droop due to temperature imbalances.

M60A2 "Starship"

M60A2 was composed of a new, narrow-profile turret placed on M60A1 hulls. The vehicle used the 152mm gun-launcher originally intended for the next US main battle tank project. The M162 gun-launcher fired the MGM-51C Shillelagh missile, also used by the M551 Sheridan. The commander sat well to the rear of the turret, and the gunner and loader each had hatches in the turret sides. Late-production M60A2s were built without bore evacuators, since they used the closed-breech scavenging system (CBSS), which used compressed air to blow any remnants of the combustible ammunition case out of the gun-launcher before the breech was opened. In M60A2, the CBSS was located below the engine exhaust louvres in the hull rear, and this made a distinctive bulge below the exhaust louvres. Due to the complexity of the fire control system and missile guidance hardware, M60A2 was sometimes derisively known as "Starship".

M60A3

M60A3 was an improved M60A1, featuring a laser rangefinder, solid state ballistic computer, and crosswind sensor. The laser rangefinder utilized the right-side rangefinder blister. In August 1979, the AN/VSG-2 tank thermal sight was added to M60A3s to allow better passive visibility in inclement weather conditions such as smoke or fog. M60A3s equipped with this device were designated M60A3(TTS). Steel road wheels were again used starting in May 1980, since they cost less than the lighter aluminum wheels. Drivers were provided with an improved floor escape hatch lock, and the power of the turret motor was doubled, from 5 to 10 horsepower. M60A3s also were later fitted with a muzzle reference system, a Halon fire extinguishing system, a vehicle engine exhaust smoke system, and hardware to allow the mounting of equipment such as chemical alarms.

Other Configurations

Service History

United States

The M60-based M60 AVLB (Armored Vehicle Launch Bridge) and the M728 Combat Engineer Vehicle were the only variants of the M60 deployed to South Vietnam. The AVLB, commonly referred to as the "bridge tank", was mounted on an M60 tank hull, and the M728 Combat Engineer Vehicle was an M60 tank mounting a short-tubed 165 mm (6.5 in) main gun that fired a shaped charge.

Late in the M60's U.S. Army service a number of prototype upgrades were evaluated. These were passed over in favor of simply producing more M1 Abrams. Due to the end of the Cold War, surplus US Army M1s were absorbed into the remaining USMC units, allowing the Marine Corps to become an all-M1 tank force at reduced cost. Except for a small number in active service, most M60s were placed in reserve, with a few being sold to US allies.

The M60A3 participated in close air support trials with the F-16 in the 1980s. M60A1s are still used by the USAF for testing of ground radar equipment on new aircraft and for ground force adversarial work at Red Flag at Nellis AFB Nevada.

USMC M60A1 tanks were used in Grenada and Beirut in 1983. In February 1991 USMC M60A1 ERA tanks rolled into Kuwait city after a two-day tank battle at the Kuwait airport.

During Operation Desert Storm in 1991 at least one US Air Force unit was equipped with M60s. The 401st TFW (P), deployed to Doha, Qatar had two M60s for use by explosives ordnance disposal personnel. It was planned that using the MBTs would allow the EOD crews to remove unexploded ordnance from tarmac runway and taxiway surfaces with increased safety.

Israel

The Israel Defense Forces (IDF) purchased its first M60A1 tanks from the US in 1971. M60s and M60A1s saw action with Israel during the 1973 Yom Kippur War in both the Sinai and the Golan Heights (although mainly in the Sinai). The United States sent additional M60s to Israel just before and during hostilities. Following the war, the IDF received many more M48s, M60s and M60A1s from the U.S. Israel further upgraded their inventory of M60s prior to their use in the invasion of Lebanon in the 1982 Lebanon War. The Israeli modifications included new tracks and explosive reactive armor (ERA). This variant was known as the Magach. Further work in Israel has been done on the upgraded Magach models, adding new armor, new fire control system, a thermal sleeve and smoke dischargers. The latest versions, the Magach 7 (with variants A through C), are in use with some IDF units. South of Beirut in 1982 some 400 Syrian tanks including T-72s were destroyed by Israeli M-60A1s and Merkava 1 tanks. This surprised western analysts who said M-60s easily defeated newer Soviet built T-72s in combat.

In July 2013, Israel began a program called Teuza (boldness) for the purpose of turning some military bases into sales lots for obsolete IDF equipment. Older models that are not suited for Israel's forces will be sold off, or sold for scrap if there are no buyers. M60A1/A3 and Magach tanks are among those being offered. Main buyers are expected from Latin American, Asian, and African countries.

Kuwait

The M60A1 RISE Passive of the U.S. Marines saw action during Operation Desert Storm in the 1991 Persian Gulf War, opposing Iraqi armor which included the T-54, T-55, T-62, Type 69, and T-72. The M60A1s were fitted with add-on explosive reactive armor (ERA) packages and supported the drive into Kuwait City, where they were involved in a two-day tank battle at the Kuwait airport with ten tanks lost. They saw service with the United States Marine Corps and the Saudi Arabian Army.

Other users

As of 2005, M60 variants were in service with Bahrain, Bosnia, Brazil, Egypt, Greece, Israel, Jordan, Portugal, Spain, Tunisia, Turkey, Thailand, Taiwan, Iran, and some other nations to varying degrees.[16] Royal Thai Army M60A3s were engaged in combat to recapture Border Post 9631 from Myanmar Army forces in 2001, and reportedly exchanged fire with Type 69 tanks.

The U.S. military continues to have significant stockpiles of M60s waiting to be scrapped, sold-off, converted, or used as targets in weapons testing, or used for radar objects for jet attack planes. Some vehicles that use the chassis are still in use, however. Most of the M60s still used are much upgraded models. Pattons formed the basis for many 'new' tank designs, some using the chassis but with all-new turrets others using various upgrade packages. Jordan for example, is modifying two battalions of M60A3 with the IFCS system.

Greece offered to donate 13 M60A3 tanks to Afghanistan in 2007.

- XM60/M60

- Bearing a strong familial resemblance to the M48, the M60 has a wedge shaped hull, three return rollers, and aluminum road wheels, features not found on previous M48s. Featured a turret with 105 mm M68 gun. Some early production units for this and for A1 version, did not have the commander's cupola.

- M60A1

- First variant to feature the distinctive "needle-nose" long nosed turret, along with better armor protection and improved hydraulics.

- M60A1 AOS

- Add-On Stabilization, introduced in 1972 for the M68 gun.

- M60A1 RISE

- Reliability Improvements for Selected Equipment, featured improvements of almost all the basic systems including an upgraded engine design that allowed easier access to components to allow removing the engine pack in less time and a new track type, T142, that helped reduce wear and improve track life.

- M60A1 RISE Passive

- RISE, but with a smaller infra-red/white light capable search-light and passive night vision equipment. USMC M60A1 RISE Passives were outfitted with explosive reactive armor (ERA) in the late 1980s.

- M60A1E1

- Developmental test vehicles fitted with the 152 mm M162 gun-missile launchers.

- M60A1E2/M60A2

- Turret design finalized, giving the distinctive "starship" look. A variant was tested with a remote controlled 20 mm cannon as well.

- M60A1E3

- prototype, M60A1E2 fitted with 105 mm gun.

- M60A1E4

- Experimental type with remote control weapons.

- M60A3

- M60A1 fitted with a laser rangefinder, M21 solid state ballistic computer, and a crosswind sensor. Late production units omitted the commander's cupola.

- M60A3 TTS

- Tank Thermal Sight; M60A3s fitted with the AN/VSG-2 thermal sight.

- M60 Super/AX

- Uparmored versions with minor improvements. Main version also featured no optical rangefinder.

- M60-2000/120S

- M60/Abrams hybrid vehicle developed by General Dynamics Land Division. Not adopted by the United States military.

Specialized

- M60AVLB

- baseline M60-based chassis armored vehicle-launched bridge with 60-fodt (18 m) scissors bridge.

- M60A1

- Upgraded version of the M60 AVLB based on the M60A1.

- M60 AVLM

- Armored Vehicle Launched MICLIC (Mine-Clearing Line Charge), modified AVLB with up to 2 MICLIC on M60 chassis.

- M60 Panther

- M60 modified into a remotely controlled mine clearing tank.

- M728 CEV

- baseline M60-based Combat Engineer Vehicle fitted with a folding A-frame crane and winch attached to the front of the turret, and an M135 165mm demolition gun. Commonly fitted with the D7 bulldozer blade, or a mine-plow for the clearing of land mines.

- M728A1

- Upgraded version of the M728 CEV based on the M60A1.

International

- M60T or Sabra

- highly upgraded version of the M60A1 which is designed for the MBT modernization program of the Turkish Army. It features a new 120 mm smoothbore gun, electric stabilization system, new fire control system, and new armor package. M60T is also known as Sabra Mk.II.

- E-60

- Unmodified main production M60

- E-60A

- Unmodified M60A1

- E-60A Dozer

- Version with M9 bulldozer kit installed

- E-60B

- Unmodified M60A3

- M60VLPD 26/70E

- Spanish Army bridgelayer based on the M60 with "Leguan bridge system". 12 converted from M60A1.

- M60CZ-10/25E Alacran

- Spanish Army combat engineer variant. 38 converted from M60A1.

- Israeli variants

- Many of the Israeli M60s have been upgraded with additional reactive or passive armor, drastically improving their armor protection. These up-armored versions are called Magach 6 / Magach 7.

- M60 Phoenix

- Jordanian upgrade, being carried out by the King Abdullah II Design And Development Bureau.[29] Upgrade includes shoot-on-move capabilities, increased firepower (with a RUAG 120 mm smoothbore gun) and armor protection scheme upgrade.

- Samsam (Sword)

- Iranian upgraded version of M60A1 tank, fitted with reactive armor (presumably Kontakt-5), EFCS-3 Fire Control system, Laser warning system and IR jammers.

Current Countries Using the M60

-

Bosnia and

Herzegovina - 85 M60A3 40 delivered in 2012 for exercise and main mission tasks.

- Bahrain

- 180 M60A3

- Brazil

- 91 M60A3 TTS

- Egypt

- 1716 (1016 M60A3 700 M60A1)

- Greece

- 357 M60A1 RISE Passive and 312 M60A3 TTS

- Israel

- 711 Magach 6 Archuv and Magach 6 Archuv 2, 111 Magach 7 in service.

- Iran

- 150 M60A1(2010). One of firsts delivered M60 tanks was hijacked to Soviet Union in 1961.

- Jordan

- 182

- Lebanon

- 66 A3 series

- Morocco

- 437 (260 M60A3TTS, 167 M60A3)

- Oman

- 93

- Saudi Arabia

- 450 M60A1 and M60A3

- Spain

- 17 M60A3TTS (Infantería de Marina), 38 M60CZ-10/25E, 12 M60VLPD-26/70E (Spanish Army)

- Sudan

- 20

- Portugal

- 40

- Republic of China

- 450 M60A3 TTS

- Thailand

- 178 M60A1/A3

- Tunisia

- 84 (59 M60A3 Patton and 30 M60A1 Patton)

- Turkey

- 932 (658 M60A3TTS, 104 M60A1 RISE,170 M60T)

- Yemen

- 240

Fire Control Systems

ISO Group has the parts that you need for your M60 Series Main Battle Tank

Power-train & Transmission

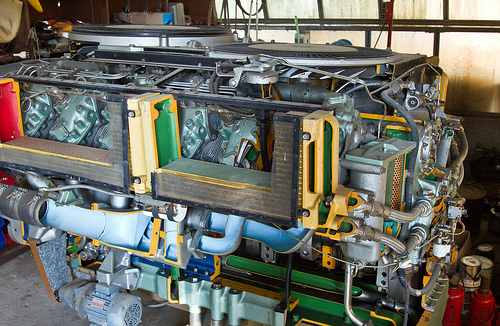

We have extensive experience in all versions of the AVDS 1790 Engines

Suspension System

ISO Group can supply the latest suspension system parts for optimized mobility

Continued Life Extension (15 Years)

ISO Group maintains inventory, manufacturer relationships, blueprint, and specification databases all for the purpose of extended support for your maintenance and overhaul requirements. ISO Group reduces life cycle costs for maintenance and overhaul facilities and governments by simplifying and efficiently managing the supply of spare parts, main assemblies and upgrades. We can provide new, overhauled, rebuilt, major components, or exchanges depending on your requirements.

Experience

ISO Group's extensive experience in global weapons system sustainment and export compliance provides a strong foundation for supporting military sustainment to foreign countries. ISO Group can support you through Direct Commercial Sale (DCS), or through the Foreign Military Sales (FMS) program. ISO Group offers support for new, as well as late model or obsolete, variants and platforms.

ISO Group's maintenance and overhaul support routinely extends equipment and material life-cycle across all land based vehicles, military air platforms, and naval vessels and equipment. Our proprietary database of inventory availability, technical manuals and drawings, and supplier performance statistics help us deliver quality products, on time.

ISO Group maintains strong supply chains that specialize in supporting the M60 series tank.

M60 Series | Technical Manuals

The M60 Main Battle Tank can readily be upgraded for advanced propulsion, mobility, armor and firepower. Fully tested modernization packages ensure continued use, improve reliability, and extend the service life by 15-20 years, as well as an increase of combat efficacy comparable to modern tanks.

ISO Group is uniquely positioned as an independent contractor to offer upgrade options for this vehicle. For each feature, multiple options can be offered. The options chosen can be integrated as a custom upgrade package for installation by the end user or a full turn-key service can be provided.

Upgrade to the latest air cooled diesel tank engine for maximum performance. The latest AVDS 1790 series engine produces 60% more horsepower as compared to the standard M60 engine.

Multiple upgrade options are available for the M60 transmissions based on engine power output. They can be provided separately or as part of a complete powerpack upgrade.

Advanced armor upgrades provide added protection against the threat of shaped-charge warheads and missiles.

Increased vehicle performance and improved quality of ride over rough terrain are just some of the improvements provided by this upgrade.

These fully-integrated systems are dependable, cost-effective, and designed to easily integrate into each M60 series tank.

Advanced technology allow for the adaptation of improved Weapon/Turret Control and Stabilization System (W/TCSS).

Fill out the form below and put us to work.